FACTORs AFFECTING CROSSDOCKING

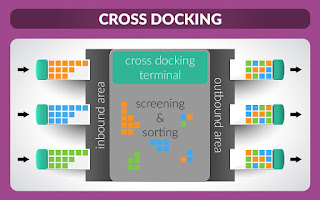

Even if Cross-Docking was used popularly in the trucking industry in 20s and later in military operations, Wal-Mart started using it in 80s and made it popular in retailing. Cross-dock is essentially a

process in a warehouse/ facility. In this process, movement of products/ goods

from receiving door to shipping door happens without/ minimal handling of

materials and with no storage. Among many of the other reasons - saving cost in

storage and delivery, faster time to market, reduced space requirement, time

effectiveness in fulfilling JIT manufacturing, and improved economies of scale

for retailers and transportation, are the main reasons because of which organizations

are inclined to extend their supply chain capabilities to adopt this process.

However, retail organizations may

have to consider many of the other aspects before adopting cross docking. Let

us consider few of the important factors which may individually or in

combination with other factors influence the decision of cross docking.

•

Nature of

business (Retail/ wholesale/ CPG etc.)

Direct to store

OR Direct Store Delivery - If Retail organizations selling products to

institutional customers (wholesalers) and if they have the orders already

placed then it also make sense for the retail organizations to place the orders

and deliver the orders directly at the customer’s store/ warehouse locations

(DSD/ DTS). This will avoid manual handling of goods/ materials at the

retailer’s warehouse location. Similar approach can also be taken for confirm

orders from own stores.

Replenishment - If retail organization have their own

stores then they may want to place bulk orders with the vendors and get it

fulfilled/ replenished from their own warehouse. E-Market place like Amazon

receives bulk orders from the vendors in the warehouse and distributing as

single units to the end customers. This type of internet order fulfilment is

another example of delivery from the warehouse location.

CPG organizations selling

products via retailers may opt to have a wide network of distribution. Sellable

inventory will be moved from production facilities by C&F agents to

distributor’s locations and from there to the respective retailers to reach

finally at the end consumers. In other words the retailing of CPG products happen

through multiple staging to cover the larger area or achieve better market

coverage.

•

Nature of

demand (High or low variance)

Looking at the

sales history, Products with high demand variance are less predictable and hence might see difference between forecast figures vs actual sales. Many of

the new products launched or during festival seasons where the demand variance

is considerably high, retailers may order the products to the vendors as per

the market response. This also helps the retailers to reduce the risk in

carrying excess inventory. These products might become good candidates for

cross docking at the retailer’s warehouses.

Products which

have reached their maturity phase in the life cycle, might have stable demand

or might have considerably low variance. Understanding this fact, retailers

might negotiate with the vendors for higher profit margin against the bulk

orders and get those delivered at the warehouse. Store/ customer side demand

can be fulfilled from the warehouse through their regular replenishment and

hence cross docking may not be required.

•

% Margin

[1-(cost/price)]

Storing the

products in the warehouse will increase cost of distribution. Inventory

carrying cost, labor cost, pick and packing cost are the main cost components.

Selling products at the retail outlets with high profile margins, bulk

discounts from the vendors may help the retailers to bear this cost and fulfill

the customer/ store orders via replenishment instead of cross docking. Most of

these products are in their maturity phase of life cycle and hence have a

steady demand throughout the year with some spikes here and there which can be

easily be accommodated through replenishment.

Products with

less profit margin may induce retailers to look for the opportunity for cross

docking as storing these products will fetch more cost hitting harder at the

bottom line.

New product

development may have heavy promotions which might experience high demand

variance for first couple of months. Keeping additional inventory may drive

some risk. A product in its maturity stage might fetch better margins and also

a stable demand from the markets. Non-availability of such products might lose

the customers. All this will be counted for the decision on cross docking or

direct to store delivery.

•

Need of

value added service (VAS) – Assembly, Grouping, Packaging etc

Some of the

products delivered at the warehouse may need some additional services at the

warehouse location. These could be printing labels, quality check, break

packing the products in smaller cases or different packing as per the customer

requirements. Some of the products like light stand, its fabric or home

furniture might need some assembly at the warehouse. Multiple ordering articles

might be repacked in warehouse as one saleable article (kidswear).

These types of

assembly, grouping, Re-packing might increase the time duration for orders to

be cross docked and hence qualify under Flow through. Flow through of these

orders from receiving door to the shipping door might happen through different

lanes (slow/ fast) depending upon time to add one/ more values.

Practically,

cross docking order might reside in the warehouse for less than 24 hours but

flow through orders might stay in the warehouse between 1-7 days.

•

Nature of

product/ item (Perishable/ fragile)

Some of the

grocery products which are perishable in nature like vegetables/ fruits. Some

of perishable products like milk/ ice cream/ raw meat require cold storage.

Such products might have shorter shelf life and hence there is special need to

deliver on time to the retail outlets. Hence such products may not be even

cross docked but might be asked to deliver directly to the retail stores

instead of any intermediate storage/ cross docking facility. These products

might not even be opted for cross docking at all. Vendors might be asked to

send the products directly to the respective demand locations (stores) and

fulfil the delivery (mostly referred as DSD – Direct Store Delivery or DTS –

Direct to Store).

•

Quality

of the item

Products with high

quality standards might not need any type of quality inspection at retailer

warehouse so these products/ items will be moved from receiving locations to

the shipping docks without any quality inspections and hence may qualify for

cross docking. This will help retailers to experience a better customer

response and appreciation for reducing the waiting period and availability.

•

Prepackaged

customer orders

Customer/ store

orders might have multiple SKUs grouped (especially in fashion) with different

colors/ variants (E.g. Pack of more than one T-shirts with different colors). Customers/

stores might want those to be sold that way and hence they might want to order

the same way. Suppliers will be asked to supply the order in pre-packaged form.

These pre-packaged customer orders might be delivered in warehouse of the

retailers and will be cross docked after printing the price labels.

• Customer

behavior (low expectation of presence of product in store, Opting no

alternative/ substitute)

This is mostly

seen in the consumer durable industry. Retailers may not be able to keep all

the models of the same/ different brands in one store due to limited space.

Customers are well aware about this fact and hence even they do not expect to

have all the products inside the store. They are also ready to wait for the

products/ models to be available/ delivered. Many of the customers already know

what they would like to buy and hence may not opt for any other substitute/ alternatives.

By looking at the catalogue, grabbing more information about the variants

available in the store, they may opt for ordering what they want over the

counter and get it delivered at their door step. Such type of buying behavior

may force the retailers to procure and deliver at the customer door step not

even at the store location.